Wear behavior of tool flank in the side milling of Ti6Al4V: An analytical model and experimental validation - Caixu Yue, Xiaochen Li, Xianli Liu, Jianbiao Du, Steven Y. Liang, Lihui Wang, Yujing

Experimental Study on Wear Characteristics of PCBN Tool with Variable Chamfered Edge | Chinese Journal of Mechanical Engineering | Full Text

The use of tool flank wear and average roughness in assessing effectiveness of vegetable oils as cutting fluids during turning—a critical review | The International Journal of Advanced Manufacturing Technology

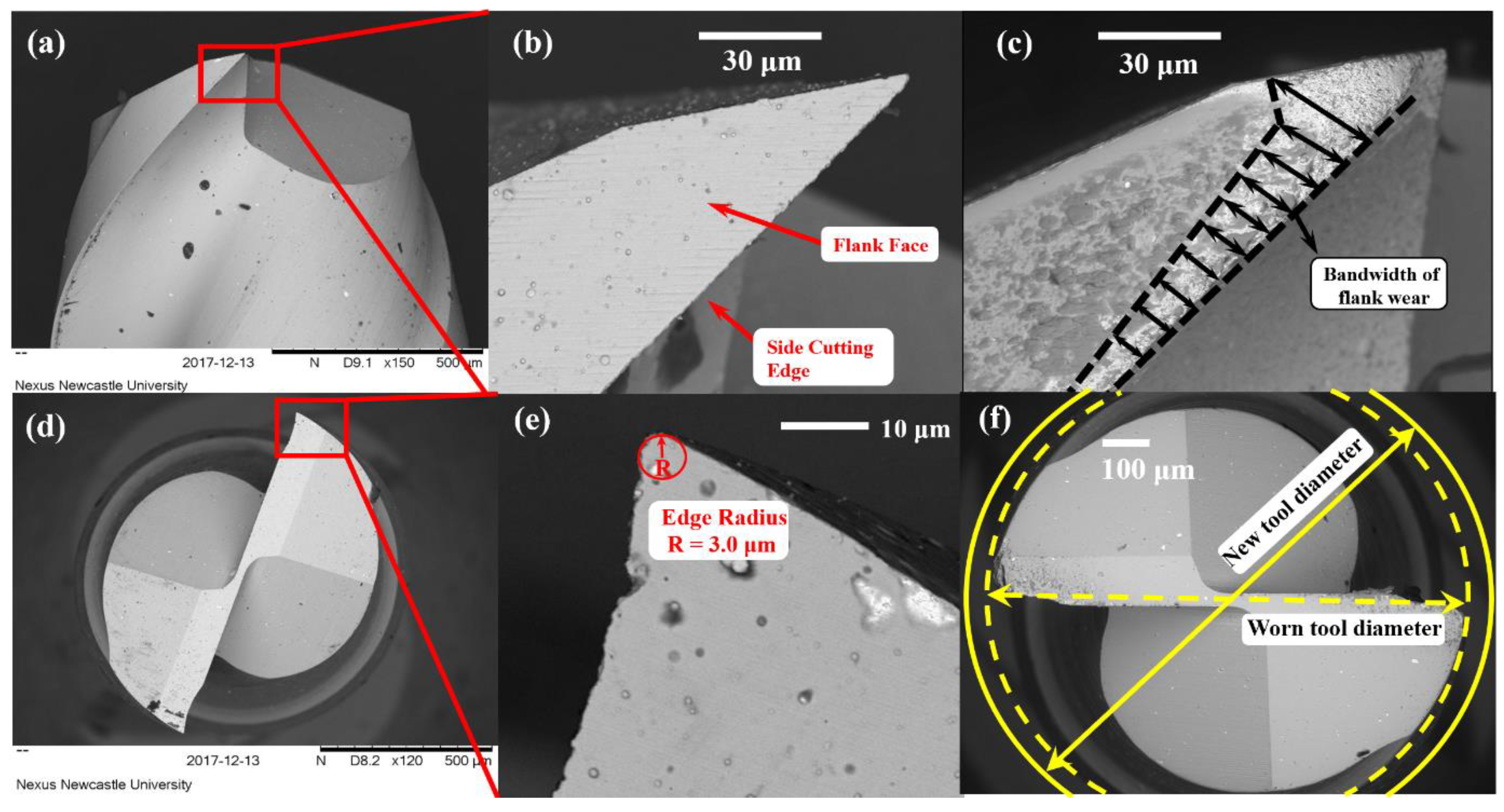

Micromachines | Free Full-Text | Study on In-Situ Tool Wear Detection during Micro End Milling Based on Machine Vision

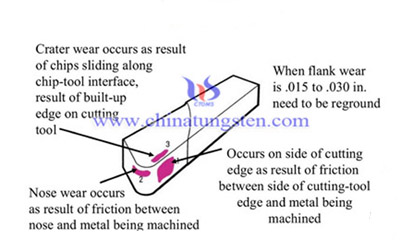

Schematic view of crater wear and flank wear at tool nose (KL: length... | Download Scientific Diagram

Micromachines | Free Full-Text | Investigation on the Tool Wear Suppression Mechanism in Non-Resonant Vibration-Assisted Micro Milling

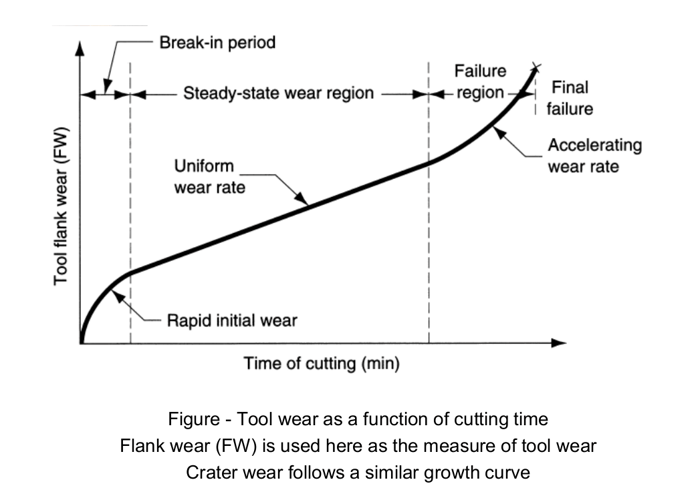

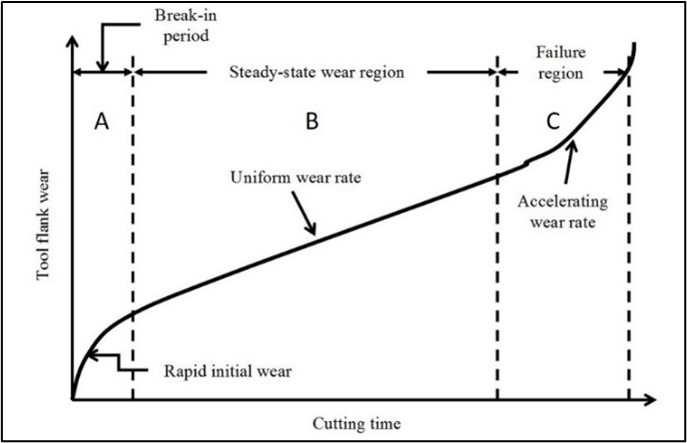

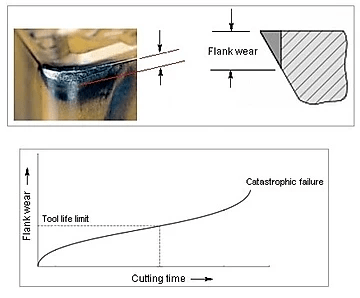

Infinity MFG - Tool wear describes the gradual failure of cutting tools due to regular operation. It is a term often associated with tipped tools, tool bits, or drill bits that are